Product Details

Processing principle

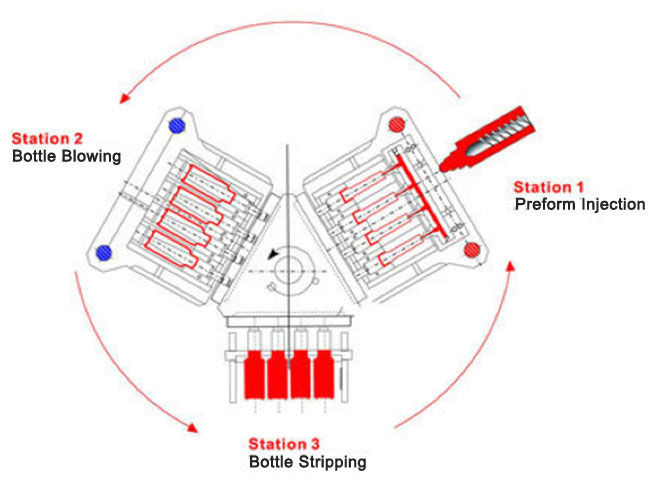

Injection blow molding machine has an accurate three-station rotary table design.After preform injection, the preform will be rotated to blow station and bottle forming, finally bottle rotated to stripping station.The bottles can be packaged directly or transported by conveyor to the next process.Because of the precise design of the mold, the I.B.M bottle has perfect neck, precise dimension, uniform wall thickness, which can meet high standard packaging needs of pharmaceutical, chemical, cosmetic and food packing industry.The I.B.M is suitable for PE, PP,PS, SAN, EVA, COC, PEEL, TPU, PETG, PLA etc material, bottle volume various from 1ml-1000ml.It is a professional equipment for high-efficiency packaging manufacturing.